Estimated reading time: 5 minutes

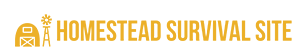

When you’re living off-grid, one of the everyday challenges people don’t always think about is laundry. Washing clothes by hand in a bucket can be time-consuming, messy, and hard on your back. And relying on electricity or fuel-powered machines isn’t always practical.

That’s why it’s worth having a simple, sturdy, non-electric washing machine. With just a barrel, some scrap lumber, and a few hardware store parts, you can build a washer big enough for jeans, towels, and blankets. This particular design is from a Youtube named Will. It's urable, easy to use, and costs under $150 to make.

Want to save this post for later? Click Here to Pin It On Pinterest!

You can watch his video and read the instructions below:

Materials Needed

- One 30-gallon closed-top plastic barrel

- 2×6 and 2×4 lumber (lengths depend on your barrel size)

- Wood glue

- 3-inch wood screws

- Schedule 80 PVC pipe and fittings (for the agitator)

- Optional Schedule 40 fittings if you can’t find Schedule 80

- Roofing screws with rubber grommets

- JB Weld (or similar epoxy) for sealing threads if needed

- A drain valve or spigot

- Teak oil (or another wood sealer)

- Tools: saw, drill, tape measure, sander, foam brush

Step 1: Build the Frame

- Cut your 2×6 lumber into four pieces to form a square frame.

- Glue and screw the corners together so that your 30-gallon barrel will fit snugly inside.

- Add four legs to the frame. Make them a little long. You can always cut them down later to adjust the height.

Step 2: Add Crossmembers and Supports

- Measure from the barrel’s seam to its edge. Add 3¼ inches to that number.

- Install a crossmember at that height so it lines up with your barrel.

- Build a center support structure from 2x4s to keep the barrel stable. Screw and glue it into place.

- Seal the entire frame with teak oil to protect it from water.

Step 3: Fit the Barrel

- Drop the barrel into the frame.

- Cut a relief notch in the wood near the drain port so you can access it later.

- Drill a hole in the top of the barrel large enough to add clothes and water. Smooth the edges with sandpaper.

- Secure the barrel into the frame with four roofing screws for extra stability.

Step 4: Install the Agitator

- Drill holes through the 2×6 uprights and the barrel walls on both sides.

- Run Schedule 80 PVC pipe through as your agitator shaft.

- Add fittings inside the barrel to create “paddles” that will churn the clothes back and forth.

- Leave enough of the pipe sticking out on one side to act as a handle. This lets you rock the agitator back and forth manually.

- Dry-fit the agitator first to ensure it swings freely without hitting the sides, then glue the fittings.

Step 5: Add the Drain

- Install a threaded barrel plug with a ¾-inch drain valve.

- If the threads don’t match, seal it with JB Weld on the inside.

- You can attach a hose to the valve to direct water away when draining.

Step 6: Test and Use

- Load clothes, water, and detergent through the top hole.

- Work the agitator back and forth to wash the load.

- Let the clothes soak for 20–30 minutes, then agitate again.

- Drain through the valve, refill with clean water, and agitate to rinse.

- Drain again, then wring clothes by hand or add a manual ringer to the frame for easier drying.

You can watch the video below to see him using it:

Cost and Final Notes

The entire project cost less than $150, which is a fraction of the price of a commercial off-grid washer. It’s also far sturdier than most small “non-electric washers” you’ll find online, which often can’t handle heavy loads.

With this setup, you’ll have a reliable, long-lasting way to wash clothes off-grid without electricity or fuel.

Like this post? Don't Forget to Pin It On Pinterest!

You May Also Like:

Brilliant diy project! Thanks!

thank you for this…well done, very clear…even I could build this